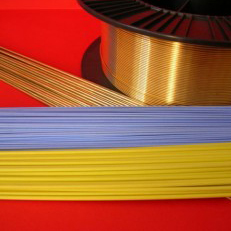

Silver brazing, sometimes known as a silver soldering or hard soldering, is brazing using a silver alloy based filler. These silver alloys consist of many different percentages of silver and other metals, such as copper, zinc and cadmium.

Brazing is widely used in the tool industry to fasten hardmetal (carbide, ceramics, cermet, and similar) tips to tools such as saw blades.

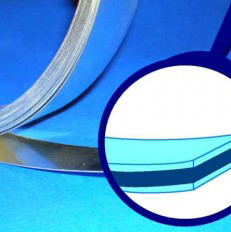

Brazed hardmetal joints are typically two to seven mils thick. The braze alloy joins the materials and compensates for the difference in their expansion rates. In addition it provides a cushion between the hard carbide tip and the hard steel which softens impact and prevents tip loss and damage, much as the suspension on a vehicle helps prevent damage to both the tires and the vehicle. Finally the braze alloy joins the other two materials to create a composite structure, much as layers of wood and glue create plywood.

The standard for braze joint strength in many industries is a joint that is stronger than either base material, so that when under stress, one or other of the base materials fails before the joint.

One special silver brazing method is called pinbrazing or pin brazing. It has been developed especially for connecting cables to railway track or for cathodic protection installations. The method uses a silver- and flux-containing brazing pin which is melted down in the eye of a cable lug. The equipment is normally powered from batteries.